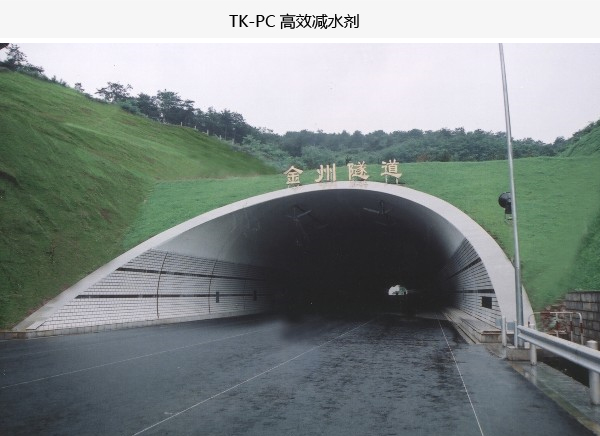

TK-PC superplasticizer, mainly used in concretes for highways, bridges, power stations, tunnels and low-grade concrete in civil construction, has many technical features like high water reduction, good cement adaptability, high fluidity, and the function to improve strength and durability as well as facilitate pumping operation. Its indicators can meet the technical requirements of GB8076-2008.

2. Model and Usage

1. TK-PC1 standard type: Powder dosage 0.5-1.5%; liquid dosage 1.5-3.0%; water reducing ratio 15-22%, suitable for all types of concrete used in general construction projects.

2. TK-PC2 retarding type: powder dosage 0.5-1.5%; liquid dosage 1.5-3.0%; water reducing ratio 15-22%, retarding setting time for more than 120 minutes at room temperature; applicable to pumping concrete during the construction of bulky structure, dams, factories, bridges and tunnels.

3. Main Performance Indicators

1. Homogeneity

Test reference standard: GB8077-2012

| Test item | Unit | Quality indicator | Test result | |

| Standard TK-PC1 |

Retarding TK-PC2 |

|||

| Chloride ion content | % | ≤0.6 | 0.2 | 0.3 |

| Alkali content | % | ≤10 | 5.7 | 6 |

| Sodium sulfate content | % | ≤10.0 | 6 | 5 |

| Mortar water reducing ratio | % | ≥14 | ≥18 | ≥18 |

| Test item |

Unit

|

Quality indicator

|

Test result

|

|||

| Standard TK-PC1 |

Retarding TK-PC2 |

Standard TK-PC1 |

Retarding TK-PC2 |

|||

| Water reducing ratio |

%

|

≥15 | 20 | 20 | ||

| Atmospheric bleeding ratio |

%

|

≤20 | 0 | 0 | ||

| Pressure bleeding ratio |

%

|

≤90 | 65 | 70 | ||

| Air content |

%

|

≤6.0 | 2.8 | 2.7 | ||

| Variation of slump over 1h |

mm

|

- | ≤60mm | - | 40 | |

| Setting time difference | Initial setting |

min

|

-90~+120 | >+90 | -20 | 100 |

| Final setting | - | -50 | - | |||

| Compressiv | 1d |

%

|

≥140 | - | 156 | - |

| 3d | ≥130 | - | 148 | - | ||

| 7d | ≥125 | 140 | 130 | |||

| 28d | ≥120 | 130 | 125 | |||

| Compressiv |

%

|

≤125 | 115 | 120 | ||

4. Packaging, Transportation and Storage

Powder products are packaged in the plastic-lined poly-woven bags with a capacity of 40Kg ± 0.5Kg. Liquid products are packaged in drums with a capacity of 220kg ± 1kg or stored and transported in tankers.

Powder shall be prevented from rain, moisture, and stored in a cool warehouse; its shelf life is two years; the shelf life of liquid product is six months. Any product must be tested before use if the shelf life expires.